As a custom case factory, HQC Aluminum Case often get different requirements from customers. To share how we do the case with customers, we show a story to you.

At the beginning, we got the inquiry from a America customer:

Hi Mr. Vince Zhang,

I am looking to make custom cases to be used for kids. I would need about 100 to start.

I would want it to look like the sample case picture #2 I have attached. I created that by myself by using a case I purchased (picture #1). The dimensions of this case were: 8.25 x 5 x 2.5 inches. I would need something in similar size (again, it's for kids, so it should be similar to this smaller size - nothing too large).

The most important part is for it to say in big white text "customer logo" on both sides of the case. Inside, it can be very simple, with either some soft foam or wave foam across the full lining - no custom cutout is needed. I do not need to have a number lock or even a key lock - all I need is for it to be closed, so something simple like lock A1009 or something similar would work.

I am located in New Jersey, USA. Please let me know if this is something your company can create and help me with. If so, I would love to know what the price could be.

Thank you very much,

Dennis

For this style inquiry, it will save too much time for both of us and customers. Because customer import this style aluminum case before. They know their quality requirements and relation problem. But, we must treat is very well too, customer know what they want, we must do better to prove our aluminum cases, if not, they will not place trial order to us.

Firstly, we must check the cases better and try to give reasonable prices to customers.

It is good beginning, customer like our prices. And we have chance to show more information of our cases and our service.

After we confirm all the parts of case, we must to sample for customer. Then send detail pictures to him.

We put our own ring to this custom case, then send pictures with rule, it will help customer to understand it well. When we did this sample, we solve another questions of foam which customer did not find before. For the depth of cut part, we just keep half height of ring, if not, maybe it is difficult for final customer to pick them up when they need.

After we did all these parts, customer placed first order directly:

Hi Vince,

I am good with the price per piece and ordering MOQ of 100 pieces.

In terms of ex-work, as we had previously discussed, I would like you guys to take care of sending it through a company like FedEx/UPS/DHL so that they can take care of all shipping and customs for me. Is this still possible? If so, can you please provide an updated cost for this?

For payment, I would prefer to do some sort of split. I saw on some of your pages a 30% deposit after order, then 70% balance against b/l copy. Can we do something like this?

Thank you,

Dennis

For the production, we did all of them as same quality as sample. And check every aluminum case for customer. It could insure every case with high quality too.

Hi Vince,

I hope you are doing well!

I am interested in ordering more cases. The cases should be exactly the same as last time. But I would please like to make sure that the corners are more clean. Some cases have bigger scratches that are noticeable, and almost every case I have to clean the corners to remove a little bit of sticky glue/oil or whatever it is. Some cases even have lots of sticky glue on the corners and it requires a lot of time to really take the glue off (see picture). If the cases are clean and less scratched, I will be able to be more efficient with them and move through them better/faster — which will likely lead to ordering more. Right now I spend a lot of time on each case wiping/cleaning every corner.

For quantity, I am thinking a little more this time.

- Is there a better price for a larger quantity? I’m currently thinking maybe about 200 cases.

- How long would it take to produce?

- Can you please remind me what would be the best way to ship the cases — I think with 200, maybe express shipping will still be less expensive and faster? I am open to your suggestions.

- Do you know of any tools or ways for me to customize the cases when I get them? For example, if I want to put a kid’s name on the case, is there any tool/technology that can do it? The only way I can think of is by using stickers to spell out a name, but stickers do not always stay attached well, and it doesn’t always look professional.

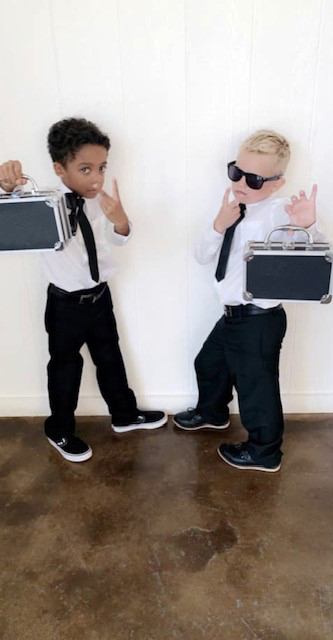

I have attached a couple pictures of kids using the cases you make for me! My goal is to keep growing this idea/business. The more it grows, the more cases I will be needing. I am looking forward to your continued support!

Thank you,

Dennis

Recently, this customer placed a new order and give us more requirements. And share their pictures with us.

For aluminum cases, there are too many features:

* MOQ is only 50-100 per time. And most time do not need to make mold.

It could save too much cost for customers.

* It is light-weight style case, but, it is strong too.

* Color, accessories and inner lining could do OEM or change to meet customers` need

* Production time is short( within 7-30 days)

HQC Aluminum Case welcome you, and try to find good ways to solve your requirements of cases.

More Detail view: https://www.hqc-aluminumcase.com/